Exploring the Craft of Diecasting: Precision in Manufacturing

Exploring the Craft of Diecasting: Precision in Manufacturing

Blog Article

When it comes to manufacturing, accuracy and precision prevail, and one method that exhibits these characteristics is diecasting. Diecasting is an extremely specific process which involves the injection of molten metal into a mold cavity at the pressure of a high. This technique is renowned for its capability to create precise and top-quality metal components with precise tolerances. Being the basis of a variety of sectors, ranging from automobile to electronic, diecasting is a pivotal role in shaping the modern world.

Diecasting, as it is known is a production process that involves the injection of molten metal into the mold cavity at intense pressure. The mold, which is typically made of steel, has been created to mimic the shape of the final item. This process allows the creation of detailed and intricate parts that have tight tolerances thus making it the preferred option for businesses that require precision as well as consistency. Zinc, aluminum, and magnesium are among the most widely used metals for diecasting because of their advantages, including light weight, durable, and excellent thermal conductivity.

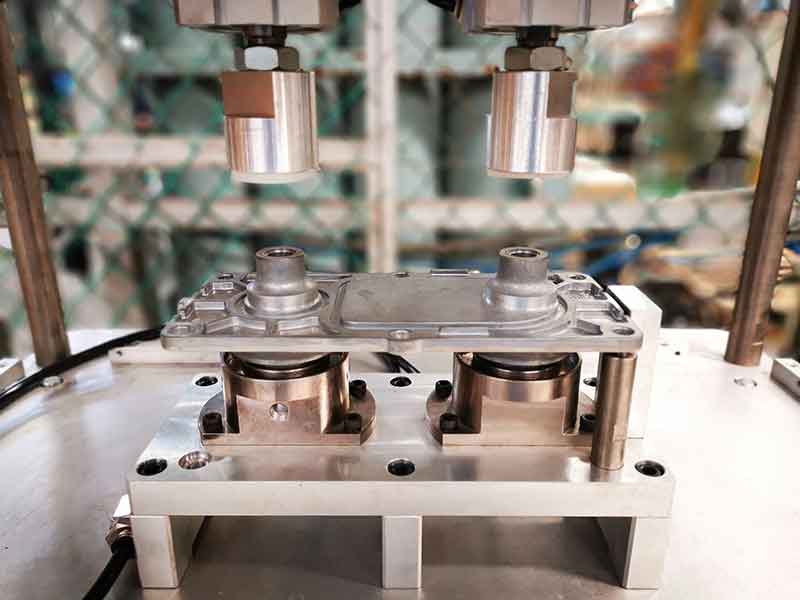

One of the key advantages of diecasting is its capacity to produce parts with exceptional precision in dimensional measurement and finish. High pressure applied during the casting process ensures that the molten material fills every single detail in the mold. This produces components with precise tolerances, and very little post-processing needed. The level of precision achieved is critical in fields in which even the smallest deviation from the specification could cause performance problems or product failures. Diecasters employ rigorous quality control procedures to examine each component, and then verify the quality of the product in order to make sure it is meeting the requirements of strict customers.

In addition to material selection The diecasters should also concentrate on mold design and maintenance. Molds, or dies acts as the blueprint for the final product informing its form, measurements and finish. Diecasters cooperate closely with engineers, toolmakers and toolmakers in order for molds which can be able to withstand the stress of high-pressure casting while ensuring precise replication of fine details. Additionally, routine cleaning and examination of molds is vital to ensure they are free of the possibility of defects, and to extend their lives. Being proactive with mold maintenance, diecasters protect the quality of their production process. To receive extra information please Visit Website

In addition to its precision and adaptability, diecasting extremely efficient with shorter cycle times and higher yields. The ability to rapidly produce big quantities of parts makes diecasting an ideal solution for production scenarios that require mass production where cost-effectiveness and scalability are vital. By minimizing material waste and maximising throughput, accidents make it easier to streamline manufacturing processes as well as reduce the overall cost of production, making it a preferred technique for manufacturing high-volume parts in fields such as electronic and automotive appliances.

As technology continues to evolve diecasting technology is undergoing innovations that enhance the efficiency and sustainable. Diecasting machines that are advanced and outfitted with monitoring systems in real time and predictive analytics optimise processing parameters to achieve maximum effectiveness and a minimum amount of production waste. Further, the integration of renewable energy sources and closed-loop recycling methods reduces environmental footprint of diecasting operations in line with international efforts towards sustainability. Diecasters are at the forefront of this trend, using modern technologies that drive constant improvement and meet the evolving demands of the market.